North American and European projects are struggling to convert dangerous levels of carbon in the atmosphere into green energy on a commercial scale.

Harvard physicist David Keith, Microsoft co-founder Bill Gates and oil sands pioneer Norman Murray Edwards are working to decarbonise the global economy by extracting carbon dioxide (CO2) using giant fans to make clean, carbon-neutral synthetic diesel and petrol.

Direct air capture, water electrolysis and fuels synthesis, it is hoped, will produce liquid hydrocarbon fuels or mechanise photosynthesis.

The individual technologies already exist but their combination on an industrial scale could be significant.

The challenge is to bring the cost of the process to below US$40 per tonne of carbon removed, since this is the estimated cost to the ecosystem of our current emissions. Most methods cost more than US$100 per tonne at present.

Global Thermostat (US), Carbon Engineering (Canada) and Climeworks (Switzerland) are investigating the process.

Climeworks built a small plant which fed absorbed CO2 into a greenhouse and opened a small-scale commercial plant in Iceland. This aimed to remove 1,000 tonnes of carbon dioxide from the air per year and pump the carbon dioxide, with water, into subterranean basalt rocks, using Iceland’s abundant geothermal power as a source of energy. The plan is to turn carbon dioxide into stone, where it mineralises rapidly because of the type of rock and the pressure. The carbon dioxide, turned to stone, is out of the energy system for millions of years.

Carbon Engineering, the company set up in 2009 by Keith, with investment from Gates and Murray, has constructed a prototype factory, installed large fans and has been extracting around a tonne of CO2 every day for a year. At present it is only being released back into the atmosphere.

Carbon Engineering and Californian energy company Greyrock have begun directly synthesising a mixture of petrol and diesel, using only CO2 captured from the air and hydrogen split from water with clean electricity. The process is being called air to fuels (A2F).

“A2F is a potentially game-changing technology, which if successfully scaled up will allow us to harness cheap, intermittent renewable electricity to drive synthesis of liquid fuels that are compatible with modern infrastructure and engines,” said Geoff Holmes of Carbon Engineering. “This offers an alternative to biofuels and a complement to electric vehicles in the effort to displace fossil fuels from transportation.

“We think our pilot plant is the first instance of air to fuels where all the equipment has large-scale industrial precedent, and thus gives real indication of commercial performance and viability, and leads directly to scale-up and deployment,” Holmes added.

“A2F is the future because it needs 100 times less land and water than biofuels, and can be scaled up and sited anywhere,” Holmes told the Guardian. “But for it to work, it will have to reduce costs to little more than it costs to extract oil today and, even trickier, persuade countries to set a global carbon price.”

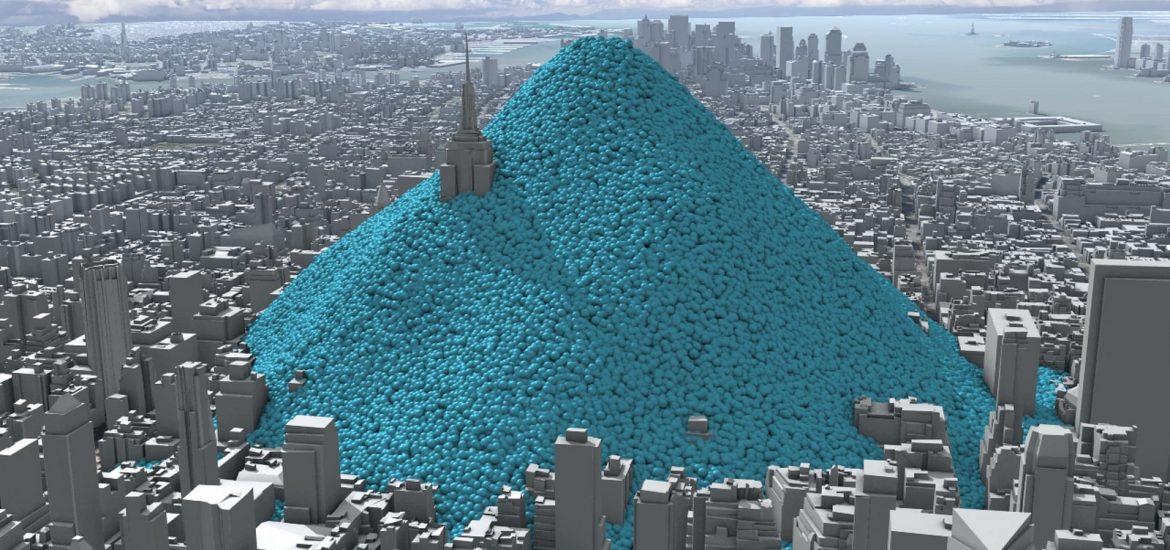

New York City’s daily carbon dioxide emissions as one-tonne spheres. Picture credit: Flickr